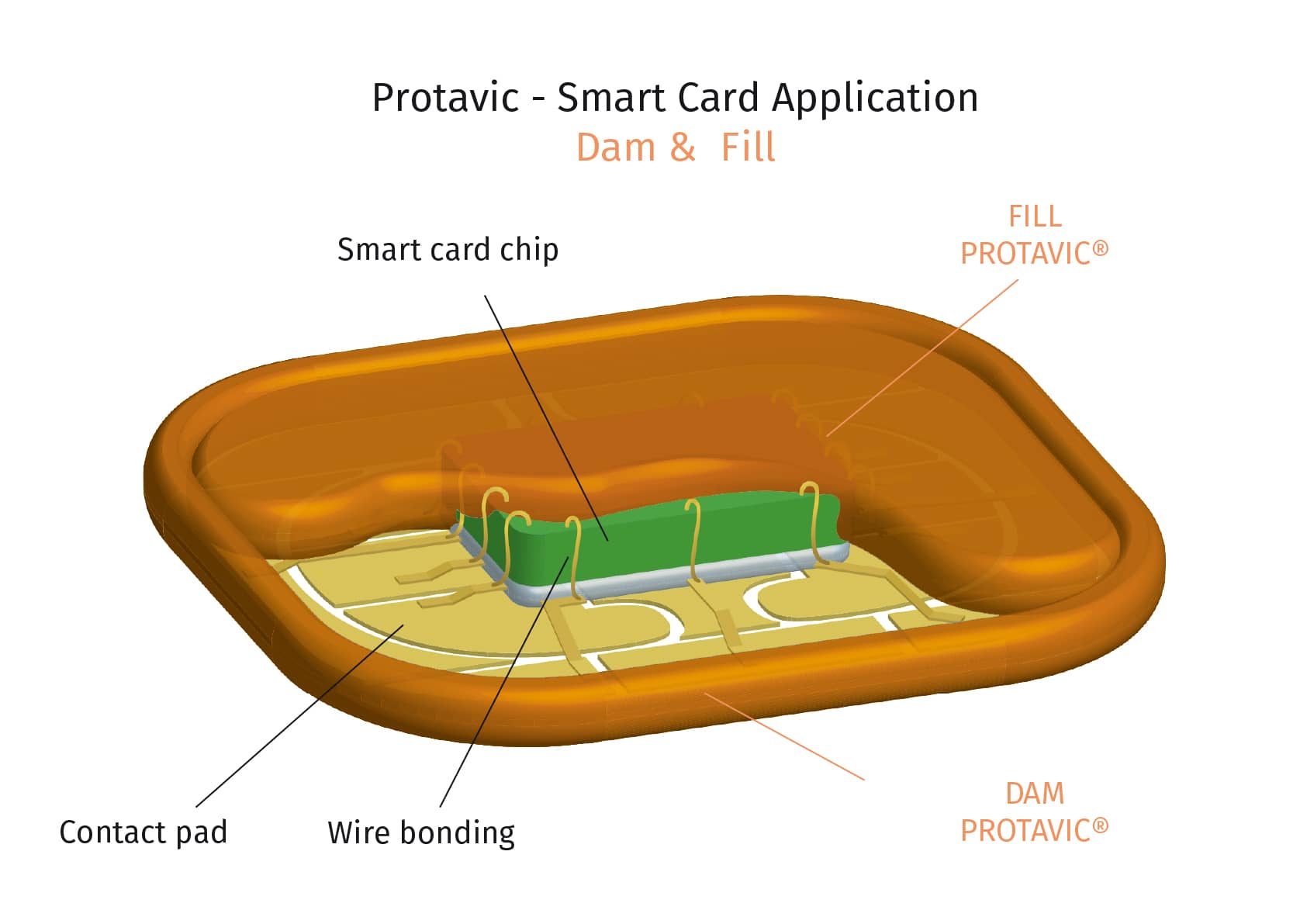

Dam & Fill and Glob-Top

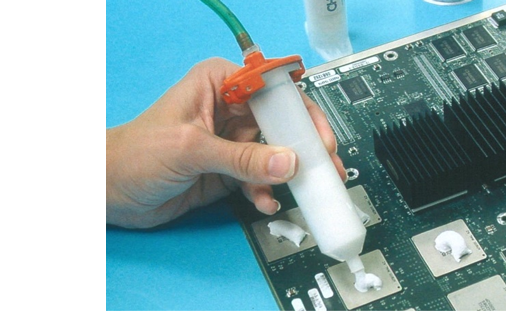

PROTAVIC’s Dam & Fill reduces warping and provides superior protection during torsion and bending tests undergone by micro-connectors during validation.

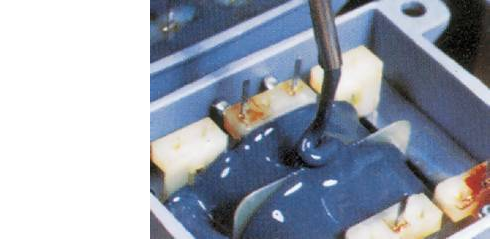

PROTAVIC’s Glob-Top is intended for smaller chips.

PROTAVIC’s Dam & Fill and Glob-Top ranges offer different curing options for protecting smart card micromodules:

- UV curing allows for quicker processing in mass production

- Thermal curing allows for low coefficients of thermal expansion (CTE) and high glass transition temperatures (Tg).

Some examples are listed in the table below.

Technical description

Name名称

Color颜色