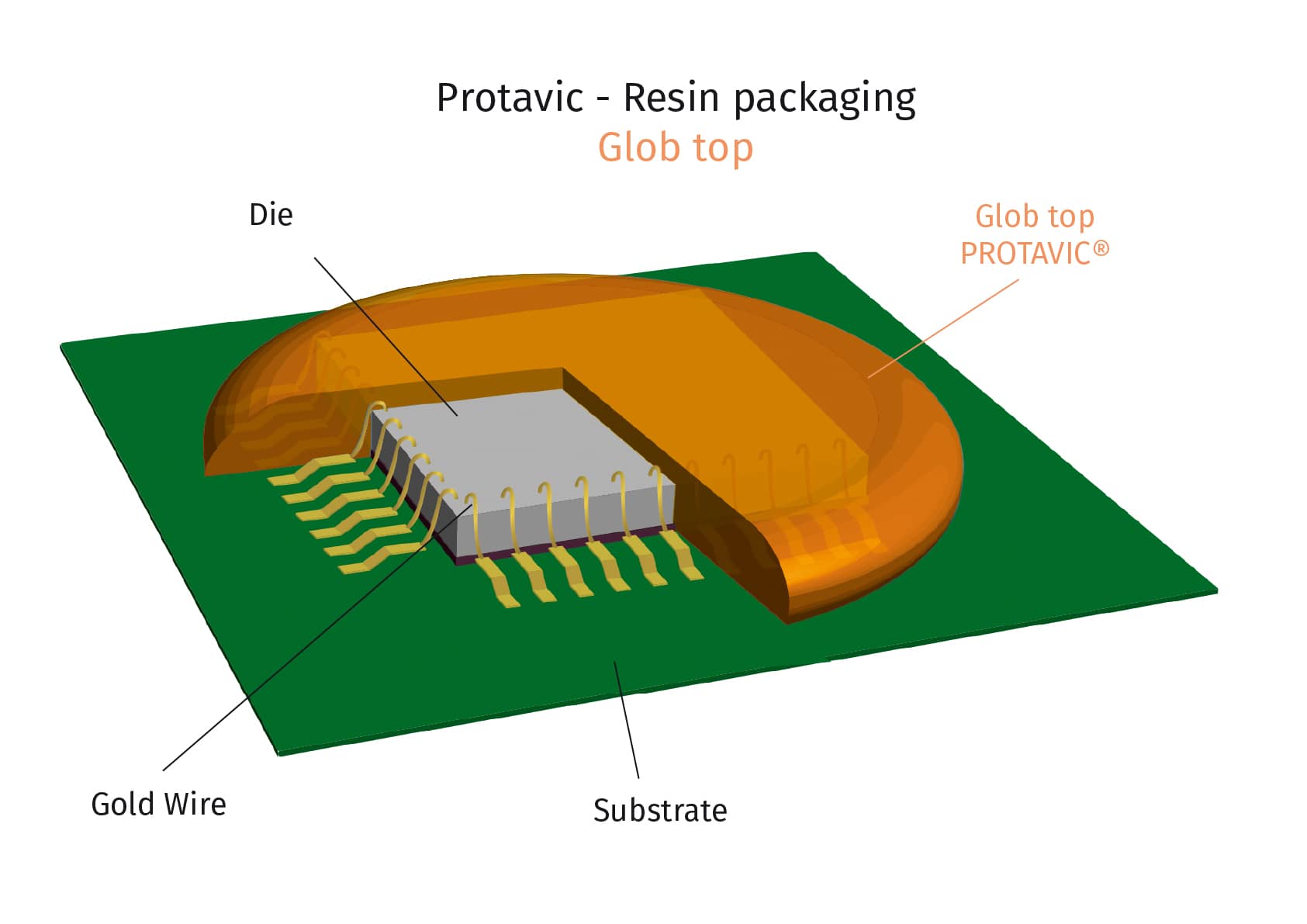

Dam & Fill and Glob-Top

The Dam & Fill combination allows for coating a specific area within a set of components. The PROTAVIC line includes products with high glass transition temperature and low coefficient of thermal expansion.

Dam & Fill protects sensitive components by providing resistance to thermal and environmental stress.

Glob-Top coatings offer the same protections for smaller chips.

Through a diverse product line with a range of chemical and physical properties, PROTAVIC covers all possibilities.

Some examples are listed in the table below.

Technical description

Name名称

Color颜色

Chemistry

Density

Viescosity at 25°C(mPa.s)

Glass transition temperature(TG)

CTE(ppm/°C)

Shore hardness

Thermal conductivity(W/(m.K))

Use

Dielectric strength(kV/mm)

Open time

Polymerization/Crosslinking

Storage

Associated Fill product

Thixotropic index of the Fill

PROTAVIC® PNC 20120

Black

Cyanate ester

1.7

25000

210°C

25

D95

-

Dam

-

24 hours

30 min at 150°C + 4h at 200°C

6 months at -20°C

PROTAVIC® PNC 20014

1.3

PROTAVIC® PNE 30252

Black

Epoxy

1.76

105000

140°C

24

D90

-

Dam

-

24 hours

20 min at 150°C

3 months at -20°C

PROTAVIC® PNE 30270

-

PROTAVIC® PNE 30270

Black

Epoxy

1.7

70000

150°C

20

D85

0,7

Fill

>15

24 hours

35 min at 120°C + 1h at 150°C

6 months at -20°C

PROTAVIC® PNE 30252

-

PROTAVIC® PNE 90595

White

Epoxy

1.4

16000

24°C

160

D50

-

Dam

-

-

30 sec at 120 mW/cm² UV A

6 months at 5°C

PROTAVIC® PNE 90295

1.1

PROTAVIC® PNC 20120

Black

Cyanate ester

Chemistry1.7

Density25000

Viescosity at 25°C(mPa.s)210°C

Glass transition temperature(TG)25

CTE(ppm/°C)D95

Shore hardness-

Thermal conductivity(W/(m.K))Dam

Use-

Dielectric strength(kV/mm)24 hours

Open time30 min at 150°C + 4h at 200°C

Polymerization/Crosslinking6 months at -20°C

StoragePROTAVIC® PNC 20014

Associated Fill product1.3

Thixotropic index of the FillPROTAVIC® PNE 30252

Black

Epoxy

Chemistry1.76

Density105000

Viescosity at 25°C(mPa.s)140°C

Glass transition temperature(TG)24

CTE(ppm/°C)D90

Shore hardness-

Thermal conductivity(W/(m.K))Dam

Use-

Dielectric strength(kV/mm)24 hours

Open time20 min at 150°C

Polymerization/Crosslinking3 months at -20°C

StoragePROTAVIC® PNE 30270

Associated Fill product-

Thixotropic index of the FillPROTAVIC® PNE 30270

Black

Epoxy

Chemistry1.7

Density70000

Viescosity at 25°C(mPa.s)150°C

Glass transition temperature(TG)20

CTE(ppm/°C)D85

Shore hardness0,7

Thermal conductivity(W/(m.K))Fill

Use>15

Dielectric strength(kV/mm)24 hours

Open time35 min at 120°C + 1h at 150°C

Polymerization/Crosslinking6 months at -20°C

StoragePROTAVIC® PNE 30252

Associated Fill product-

Thixotropic index of the FillPROTAVIC® PNE 90595

White

Epoxy

Chemistry1.4

Density16000

Viescosity at 25°C(mPa.s)24°C

Glass transition temperature(TG)160

CTE(ppm/°C)D50

Shore hardness-

Thermal conductivity(W/(m.K))Dam

Use-

Dielectric strength(kV/mm)-

Open time30 sec at 120 mW/cm² UV A

Polymerization/Crosslinking6 months at 5°C

StoragePROTAVIC® PNE 90295

Associated Fill product1.1

Thixotropic index of the Fill