MERECO

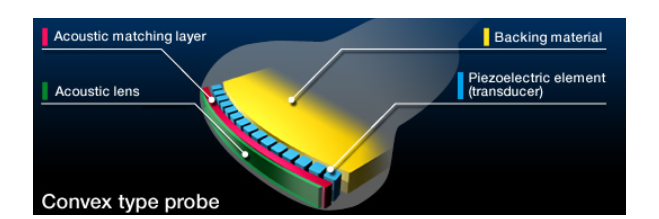

Mereco adhesives are specifically formulated for demanding applications where maximum bond strength and adequate acoustic impedance is needed for optimal performance. Mereco specilizes in bonding to low surface energy materials, CTE mismatches, shock and vibration resistance, as well as general industrial bonding applications. Mereco adhesives are widely used in acoustic probes of medical devices, oil exploration and new energy fields.

PROTAVIC acquired MERECO Technologies in the United States in 2014 to strengthen its position and technological edge in the electronic chemicals market.

Technical description

Name名称

Color颜色

Chemistry

Density

Viescosity at 25°C(mPa.s)

Glass transition temperature(TG)

CTE(ppm/°C)

Shore hardness

Thermal conductivity(W/(m.K))

Working Temp

Use

Open time

Polymerization/Crosslinking

Storage

MERECO® 350 FC

Amber

-

1.21

2000

255°C

60

D86

-

Resistant to 350°C

Full Cell

1week

1 hour @175°C + 1 hour @230°C

1 year at RT

MERECO® 3553

Blue

Epoxy

1.2

4000-5000

121°C

68

D86

-

-60°C~150°C

Optic Fiber

3hours

5 min @120°C or 1 min @150°C

1 year at RT

MERECO® ECN 809

Blue/Black

Epoxy

2.3

80000

129°C

33

D95

1.3

-55°C~205°C

Oil Drill

1.5hours

4 hours@25°C + 3 hours @150°C

6 months at RT

METREGRIP 303 SERIES

Tan

Epoxy

1.05

4000~100000

65°C

86

A80

2.4

-65°C~145°C

Transducer/Probe

8 hours

16 hours @25°C + 2 hours @100°C

1 year at RT

MERECO® 350 FC

Amber

-

Chemistry1.21

Density2000

Viescosity at 25°C(mPa.s)255°C

Glass transition temperature(TG)60

CTE(ppm/°C)D86

Shore hardness-

Thermal conductivity(W/(m.K))Resistant to 350°C

Working TempFull Cell

Use1week

Open time1 hour @175°C + 1 hour @230°C

Polymerization/Crosslinking1 year at RT

StorageMERECO® 3553

Blue

Epoxy

Chemistry1.2

Density4000-5000

Viescosity at 25°C(mPa.s)121°C

Glass transition temperature(TG)68

CTE(ppm/°C)D86

Shore hardness-

Thermal conductivity(W/(m.K))-60°C~150°C

Working TempOptic Fiber

Use3hours

Open time5 min @120°C or 1 min @150°C

Polymerization/Crosslinking1 year at RT

StorageMERECO® ECN 809

Blue/Black

Epoxy

Chemistry2.3

Density80000

Viescosity at 25°C(mPa.s)129°C

Glass transition temperature(TG)33

CTE(ppm/°C)D95

Shore hardness1.3

Thermal conductivity(W/(m.K))-55°C~205°C

Working TempOil Drill

Use1.5hours

Open time4 hours@25°C + 3 hours @150°C

Polymerization/Crosslinking6 months at RT

StorageMETREGRIP 303 SERIES

Tan

Epoxy

Chemistry1.05

Density4000~100000

Viescosity at 25°C(mPa.s)65°C

Glass transition temperature(TG)86

CTE(ppm/°C)A80

Shore hardness2.4

Thermal conductivity(W/(m.K))-65°C~145°C

Working TempTransducer/Probe

Use8 hours

Open time16 hours @25°C + 2 hours @100°C

Polymerization/Crosslinking1 year at RT

Storage