NEW VIDEO

Technical description

Name名称

Color颜色

Name名称

Color颜色

Underfill is a liquid resin that works by capillarity to protect components from shocks, drops and vibrations.

The insulating filling improves the reliability of the weld points, particularly during thermal stress and drop tests.

The low thermal expansion of PROTAVIC Underfill makes it effective in a variety of uses.

Some examples are listed in the table below.

Name名称

Color颜色

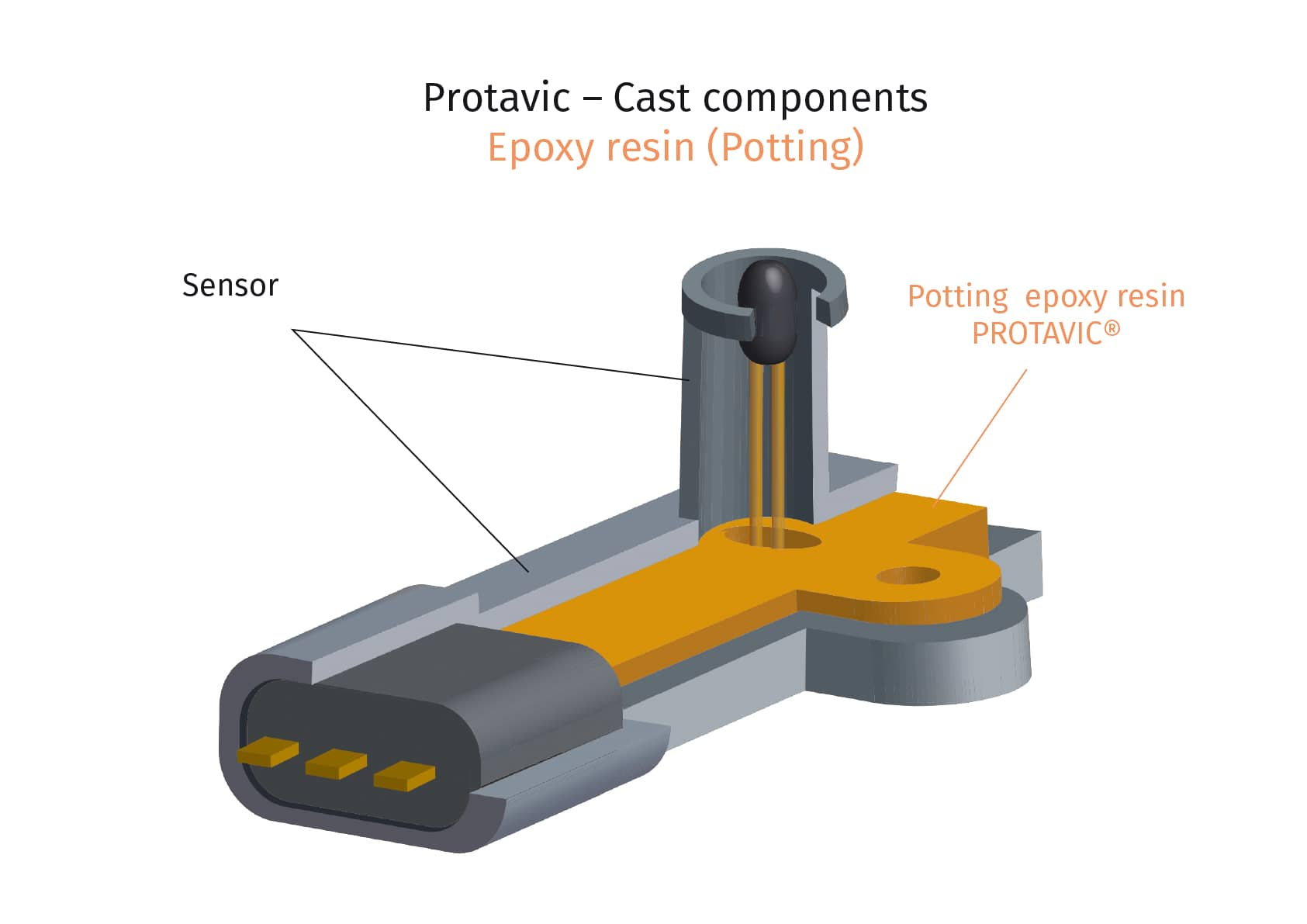

Encapsulation, or potting, is the process of pouring resins – epoxies, silicones, urethanes, hybrids – into cavities containing electronic components to insulate and hold them in place while providing protection from shock and vibration.

For example, sensitive components on PCBs require protection against external factors such as humidity, dust and chemicals.

LED assemblies, exposed to UV radiation or heat, require potting compounds as well.

PROTAVIC has developed a range of cyanate ester-based liquid resins which outperform the thermal resistance of current silicone and epoxy resins while ensuring very low CTE and strong adhesion to various substrates.

Some examples are listed in the following table.

Name名称

Color颜色

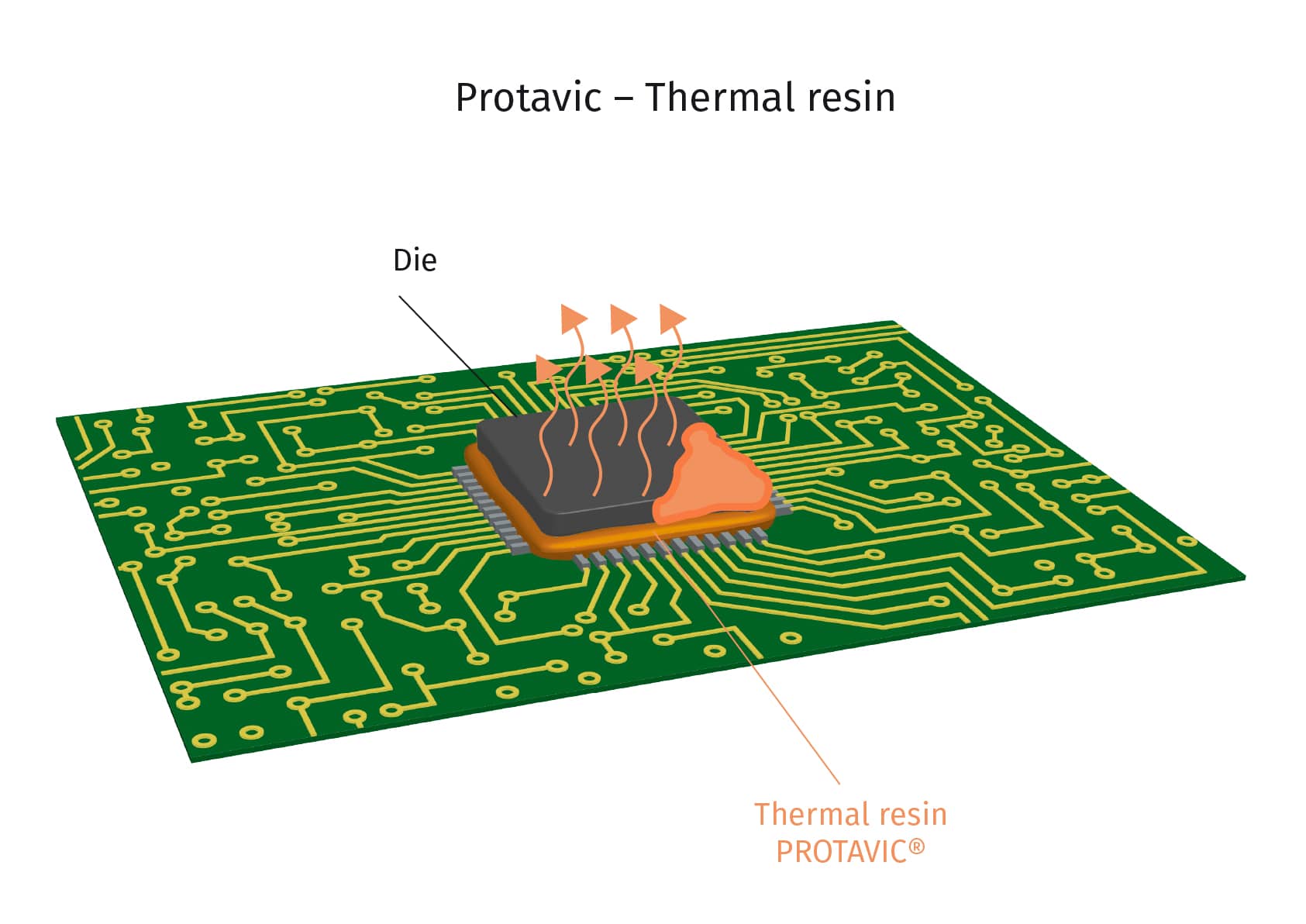

Attaching heat-generating components to electronic assemblies requires thermally conductive adhesives to avoid creating hot spots.

In addition, the miniaturization and increased power density of electronic components has led to higher temperatures, further increasing the demand for thermally conductive, heat dissipating materials.

The PROTAVIC product line meets the need for heat dissipation through thermally conductive pottings designed for optimal heat transfer.

Some examples are listed in the table below.

Name名称

Color颜色

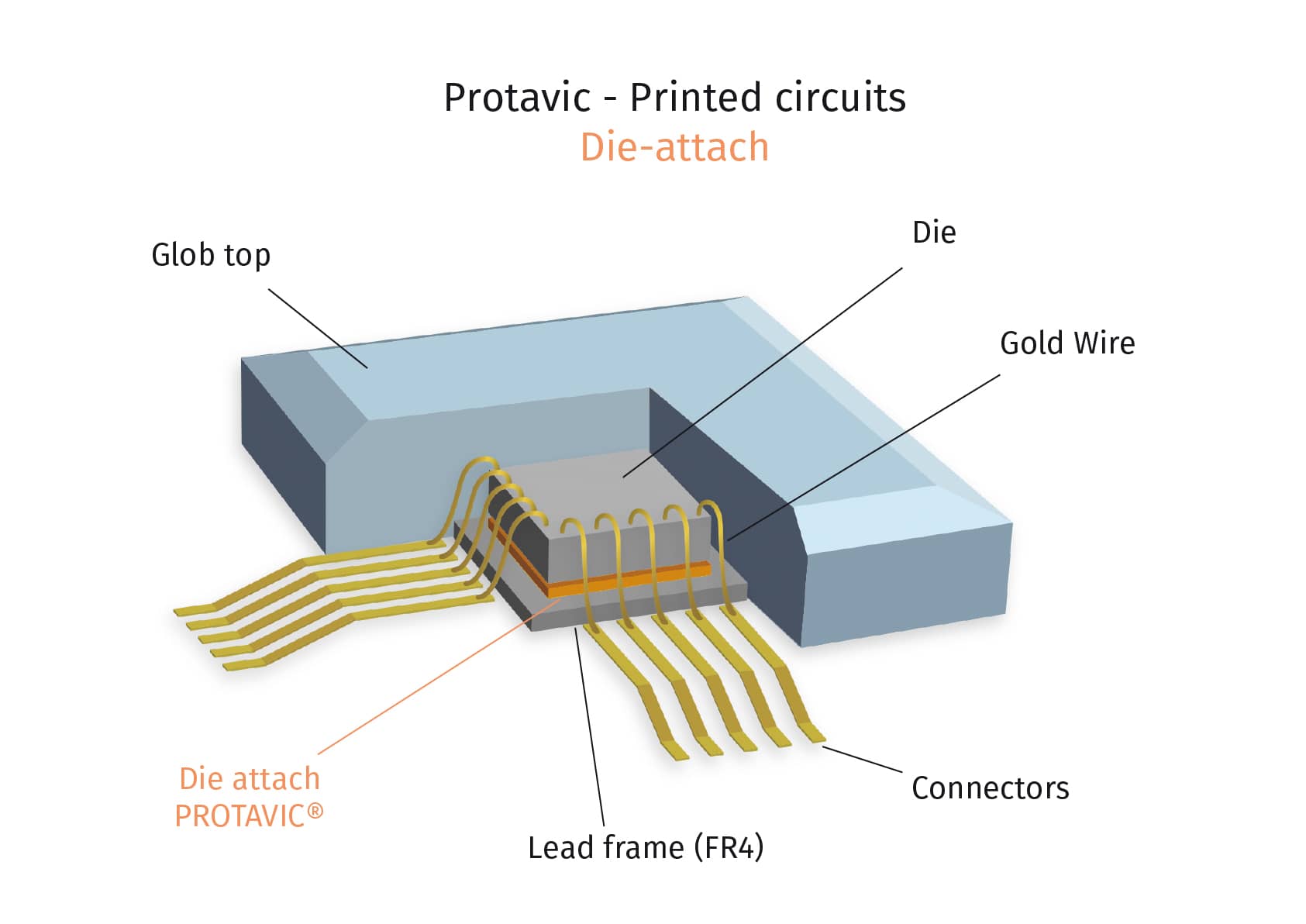

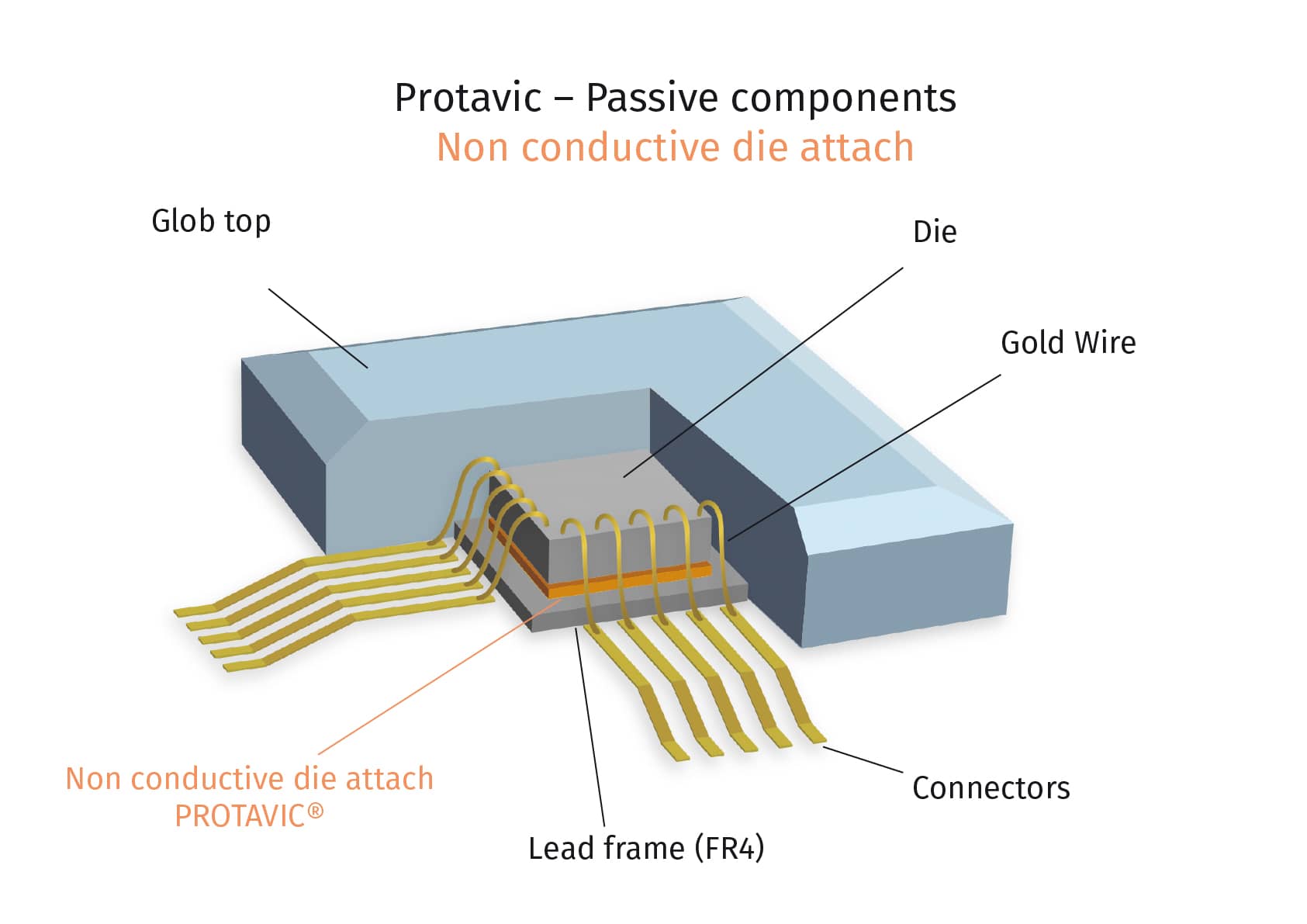

The Die-Attach process involves attaching a silicon chip to a lead frame or other substrate with an adhesive that is either electrically conductive or dielectric. PROTAVIC offers a range of adhesives specially designed for this purpose.

The choice of the chemistry depends on the final application and requirements:

PROTAVIC offers Die-Attach adhesives with high thermal conductivity, quick curing, very low CTE and low outgassing.

Some examples are listed in the table below.

Name名称

Color颜色

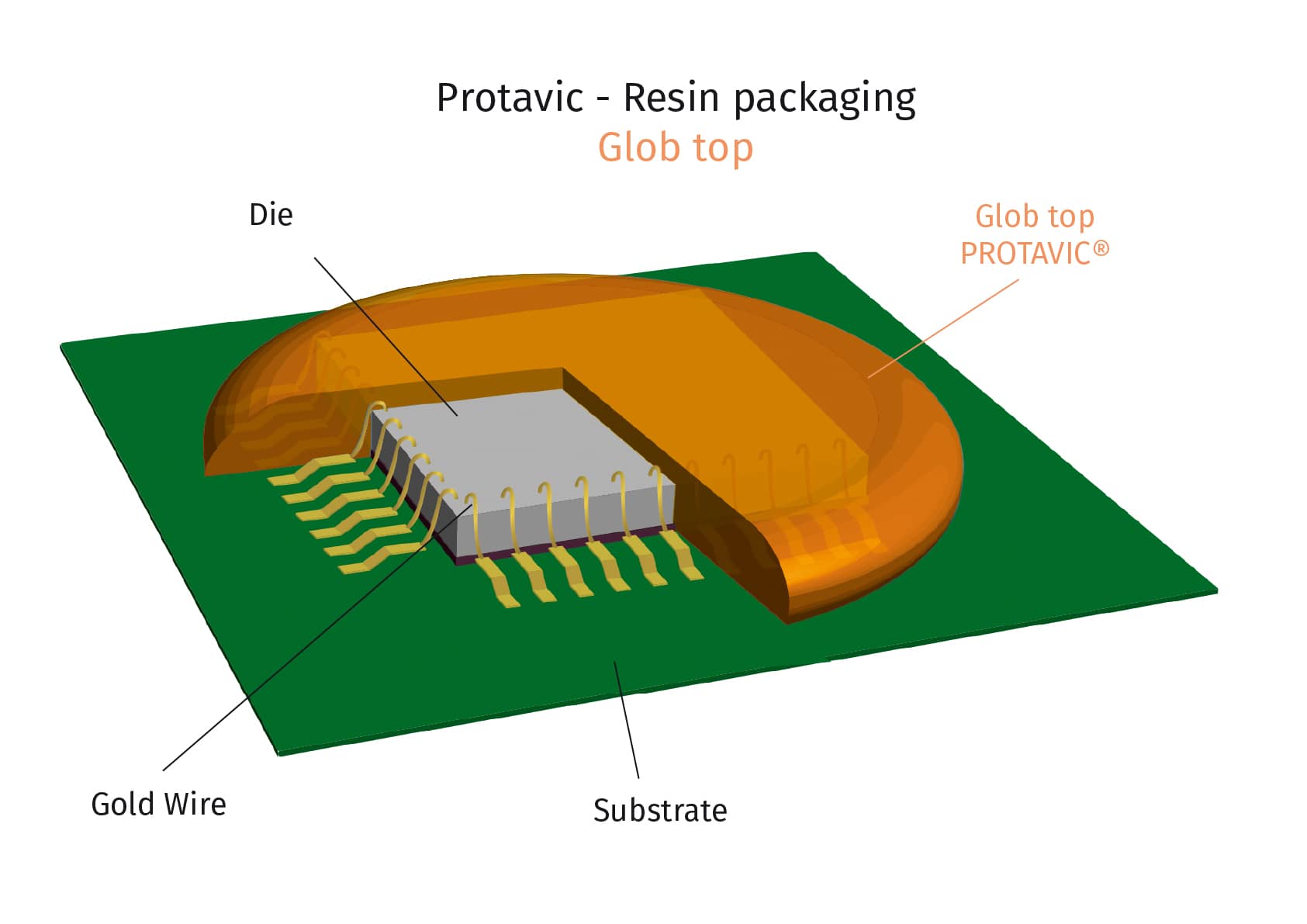

The Dam & Fill combination allows for coating a specific area within a set of components. The PROTAVIC line includes products with high glass transition temperature and low coefficient of thermal expansion.

Dam & Fill protects sensitive components by providing resistance to thermal and environmental stress.

Glob-Top coatings offer the same protections for smaller chips.

Through a diverse product line with a range of chemical and physical properties, PROTAVIC covers all possibilities.

Some examples are listed in the table below.

Name名称

Color颜色

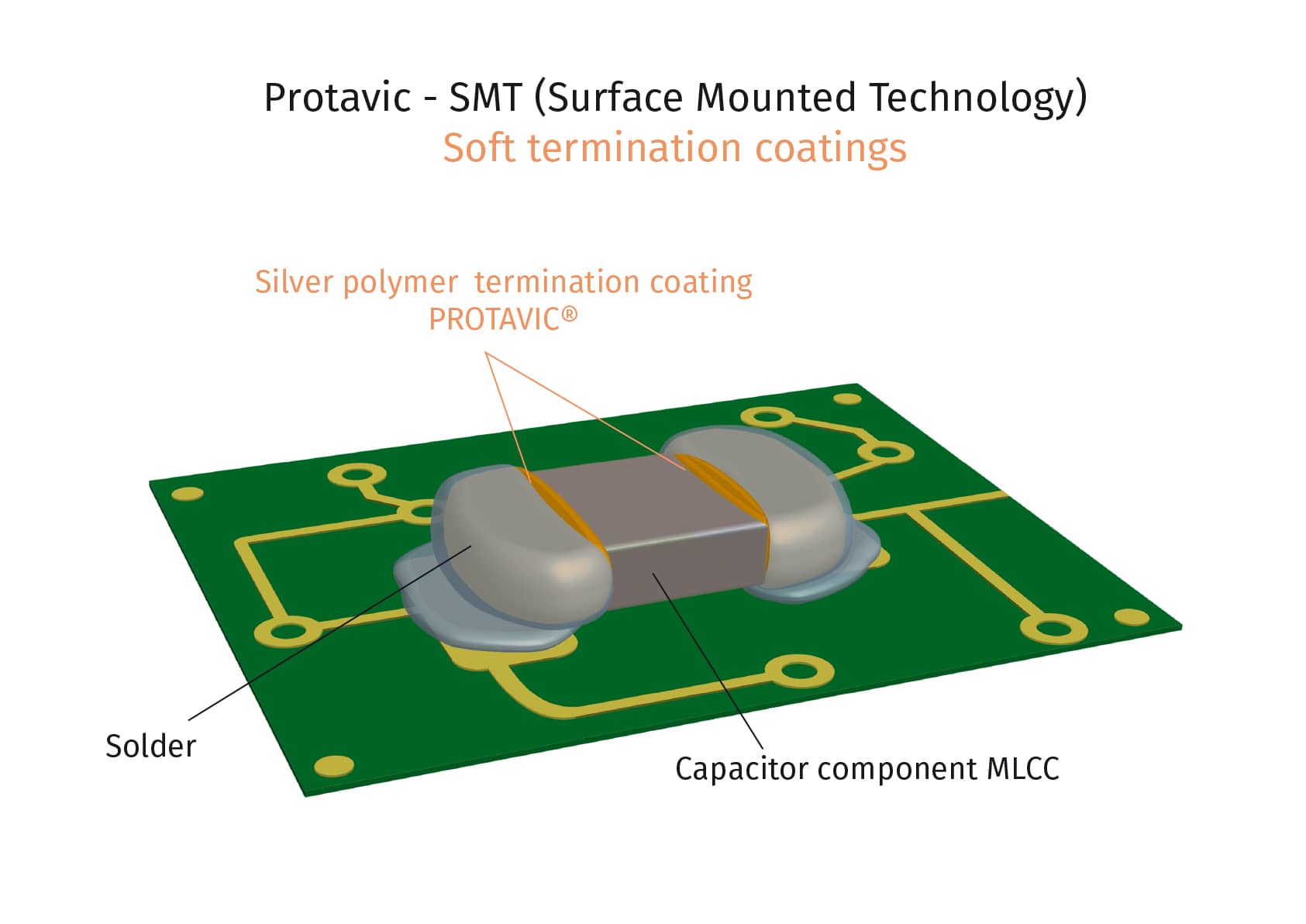

PROTAVIC termination products protect against cracks that can arise during surface mounted device (SMD) assembly from picking and placing, soldering and handling all the way through to the final tests of the circuit board (PCBA).

By providing flexibility that dramatically reduces stress cracking, the terminations developed by PROTAVIC greatly reduce the possibility of capacitor failure.

Some examples are listed in the table below.

Name名称

Color颜色

PROTAVIC offers a range of adhesive products designed for Die-Attach.

The choice of the chemistry depends on the final application and requirements:

The adhesives can be insulating or conductive with thermal conductivity up to 28W/mK.

PROTAVIC products have high ionic purity and low degassing, so they are appropriate for use in the defense and aerospace industries.

Some examples are listed in the table below.

Name名称

Color颜色

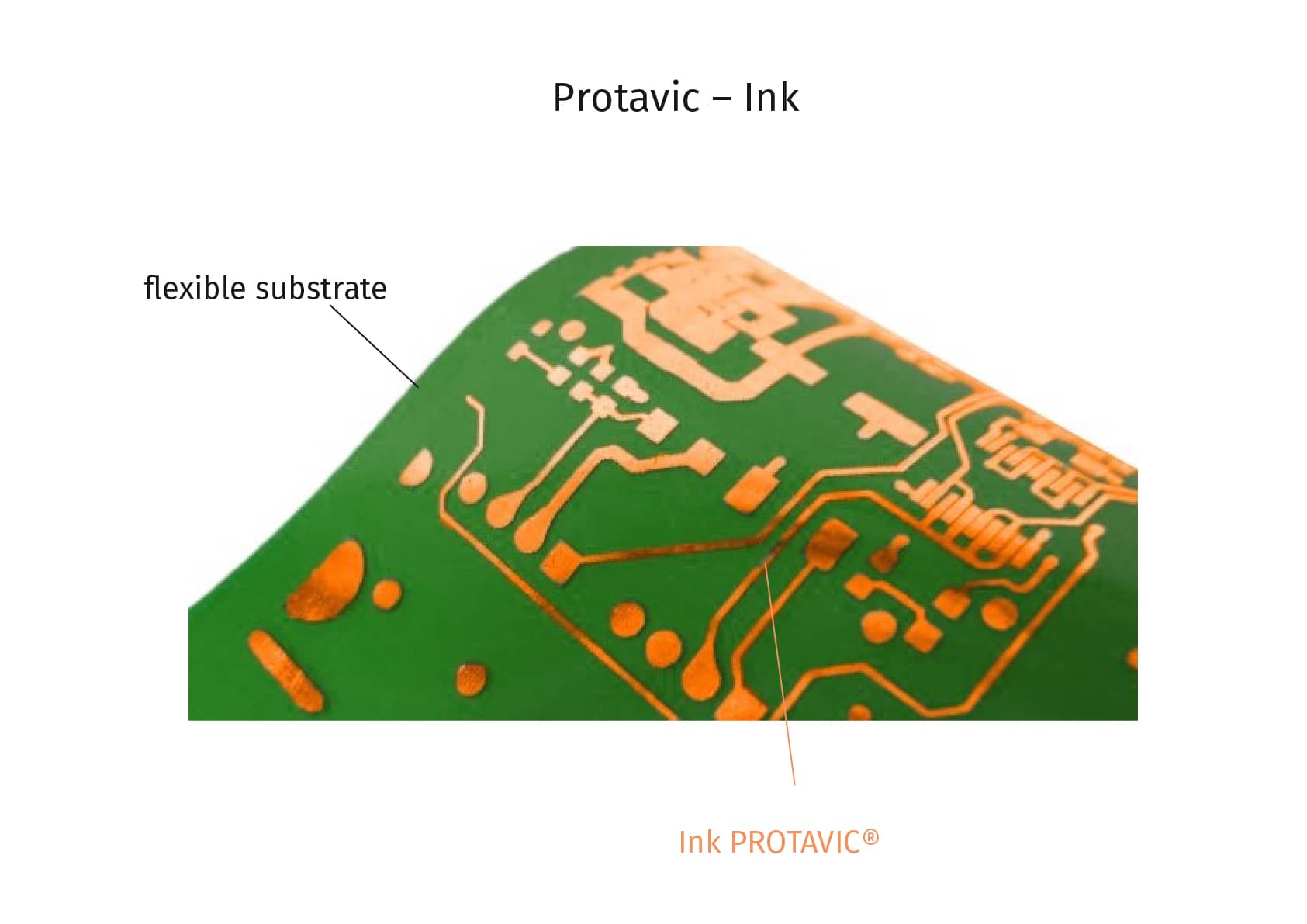

The PROTAVIC product line offers conductive inks with low-temperature curing, suitable for application on various substrates, including paper, PET and PVC.

The advantage of PROTAVIC inks is that they combine flexibility and electrical conductivity.

The application can be done by screen printing, spraying or bar-coating.

An example is given in the table below.

Name名称

Color颜色

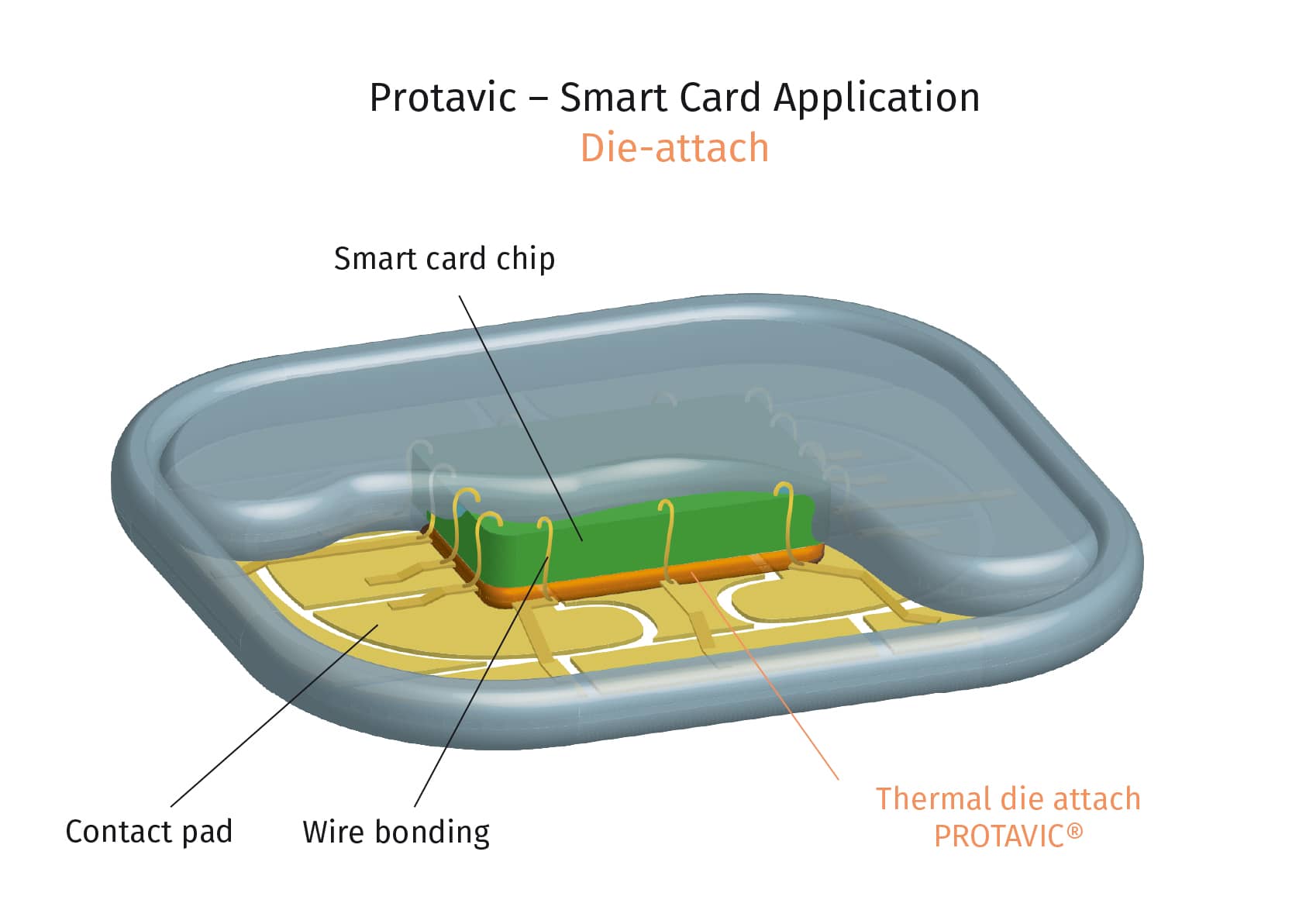

Due to the high volume of the smart card and RFID markets PROTAVIC has developed a range of Die-Attach chip adhesives that are compatible with the newer reverse “Flip-Chip” method and the traditional wire-bonding micro-connector method.

Some examples are listed in the table below.

Name名称

Color颜色